In manufacturing, even a few minutes of downtime can mean massive losses. For one leading U.S. steel manufacturer — the only producer of forged steel wheels for railcars and locomotives in North America — network failures had become a daily headache.

Spread across a 1.4-square-mile facility in Pennsylvania, the plant relied heavily on wireless connectivity to keep its 24/7 operations running — from outdoor scrap yards to melt shops and forging lines. But Wi-Fi simply couldn’t keep up. Metal walls, high heat, heavy equipment, and electromagnetic interference made stable connections almost impossible.

The result?

Frequent production halts, wasted materials, and nonstop IT support calls. Every dropped connection meant delays, losses, and frustrated staff.

The Turning Point

When Wi-Fi troubleshooting became a full-time job, the IT team made a bold move — they turned to Celona’s 5G LAN solution.

Instead of battling weak Wi-Fi signals, Celona’s private 5G network used the clean CBRS spectrum and higher power levels to cover huge areas with far fewer access points. The results were immediate and game-changing:

No more random connection drops

Seamless communication between cranes, tablets, and control systems

A dramatic drop in production disruptions

The Results That Spoke for Themselves

Before Celona, the plant faced 5–6 disruptions every week.

After the switch, the same team reported fewer than five disruptions in 18 months.

That’s a 70x improvement in uptime — with ROI achieved in just five months.

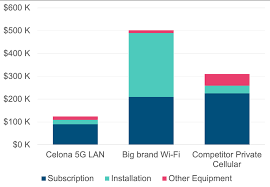

Beyond reliability, the company also cut its total network costs by over 30% compared to Wi-Fi 6, using fewer devices and far less maintenance.

Why This Matters

For industries where every process depends on the one before it, a stable network isn’t just a convenience — it’s the heartbeat of the entire operation. With Celona 5G LAN, this manufacturer didn’t just fix connectivity; it unlocked productivity, reduced costs, and gained back control.

Want to see the full story?

Download our detailed case study — “How a U.S. Steel Manufacturer Reduced Downtime and Costs with Celona 5G LAN.”

It’s a real-world look at how industrial-grade connectivity can completely transform operations.